Our Scope of Services

Turn Key Glass Plant Projects including Planning, Design Engineering, Procurement, Installation , Commissioning , Trial & commercial Production, Process stabilisation, Knowledge Transfer and Training the plant Technical Team.

Expertise in meeting clients Business Excellence.

Turn Key Solutions includes

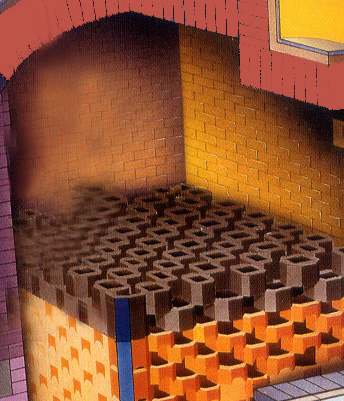

- Fuel Efficient Furnace Design, Engineering, Erection, Controlled Heat up and Commissioning

- Automatic and Semi- automatic Batch Mixing Plant & Raw material handling System

- Guaranteed Fuel Efficiency and Quantity and Quality output

- Selection, Installation and Commissioning of Forming Machinery associated Equipment, Annealing Lehrs etc

- Process Automisation , Control and Measuring systems

- Inspection , Packing Etc

- Energy Saving, Waste Reduction Management

- Supplies Include Glass Tank Furnaces, Working End Distributors, Feeder Fore-hearths, Batch Chargers, Firing system & Combustion Equipment, Glass level measuring System, Temperature and Pressure Controls, Fuel- Air Ratio Controllers, Flue Control dampers, Reversal valves, Natural and Forced Draught Chimneys etc

- Technological Innovation with Innovative Technology

- Expertise and Experience in Meeting Clients Business Excellence

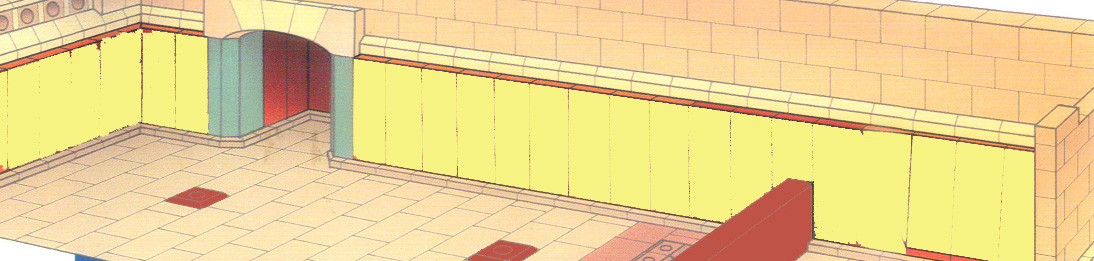

Typical Furnace Burner Port

Our services

Consultant

Complete Technical & Management support, Manufacturing and process control,Selection of Plant and Machinery..

Specialist

In Planning, Designing, Engineering and Execution of Glass Furnaces, Turn Key Glass Plant Projects. Modifications ..

Expertise

In Technical Knowhow, Manufacturing & Process Management for Glass Containers, Glass Tableware, Glass bricks ...

Our Specialisation and Expertise

- Glass Project Management

- Planning, Design & Engineering and Execution of Glass Furnaces

- Selection, Erection and Commissioning of Production and Utility equipments

- Construction, Re-construction, Controlled Heat up and Commissioning of Glass Tank Furnaces

- Hot and cold Repairs of Furnaces

- Glass Composition Control and Management, and Cost Effective Solutions

- Design , Engineering and Execution of Technologically advanced Fore hearth Coloring system

- Energy Conservation and Saving on Heating Fuels and Electricity

- Planning to Implementation of Gas based Energy Efficient and Cost effective Captive Power plants

- Conversion and Interchangeability of conventional Fuel to Natural Gas in Process

- Overhauling , Reconditioning and Re assembly of Production forming Machines

- Turnaround Sick Glass plants to sustainable Profit Centers

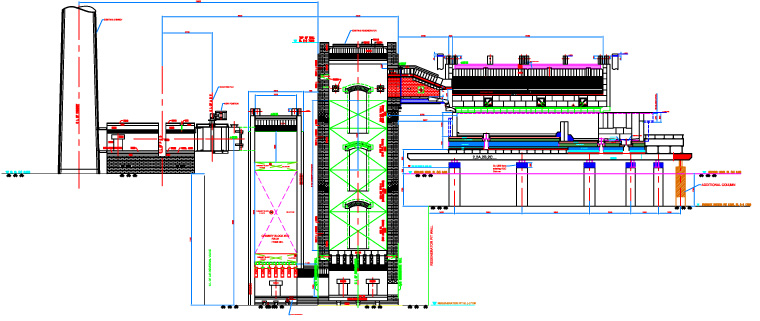

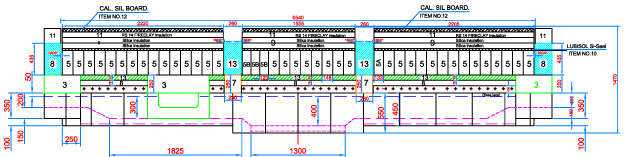

Furnace Elevation Layout

Distributor Layout